Roll Feed Cutting Plotter FC9000 series

A Flagship Model of the World Top Share Cutting Plotter Manufacturer

FC9000 is highly recognized as a cutting plotter with its best quality of finishing solution for a wide range of industries, including wide-format signage, apparel, and automotive applications. Its rigidity and media feeding quality, tool carriage performance have been improved from the previous model to enable more precise cutting.

Our newly developed Advanced Registration Mark Sensing System (ARMS) is installed which will raise the productivity with its variety of functions.

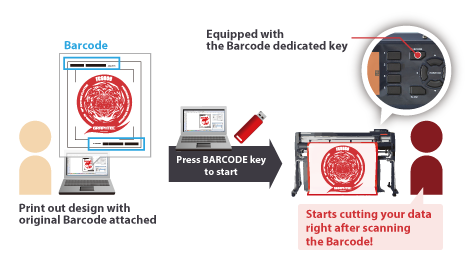

Data Link Function (Barcode Data Management/Continuous Cutting)

By reading the Graphtec original Barcode, FC9000 automatically detects its linked data from PC or USB flash memory. This function is available regardless of which printer or RIP software is used.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

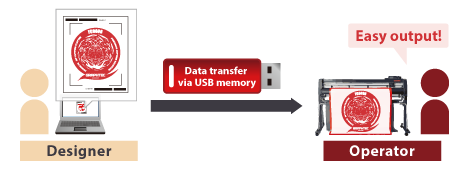

Data output via USB flash memory without PC

When cutting data designed with Cutting Master 5 or Graphtec Studio 2 are saved to USB flash memory, it can be output directly to the cutting plotter by plugging in. This simplified work-flow enables users to operate without a computer.

- The USB flash memory format only supports FAT32. Please note that NTFS and exFAT are not supported.

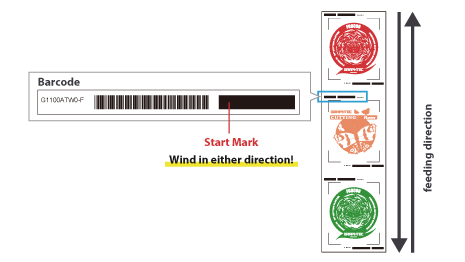

Continuous Cut (Data Link function)

Barcode data management allows cutting different data sequentially by detecting the “Start Mark” of the new Barcode. Sequential Print & Cut process with roll-media is now available.

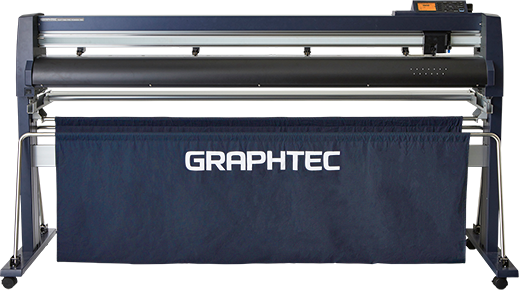

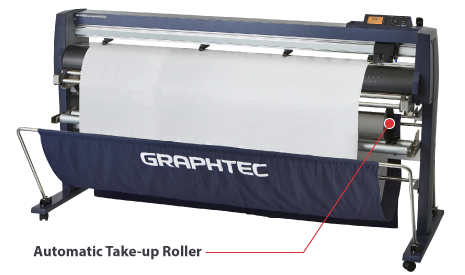

Reliable long-length tracking (Automatic Take-up Roller)

It supports long-length, 15m (50ft) (Operated with Graphtec specified media and conditions.) and makes possible to cut large signs/pops with stable paper carriage and high accurate cutting quality. In addition, if Automatic Take-up Roller as option is equipped to plotter, it becomes possible to automatically wind media and improve your work efficiency.

Automatic Take-up Roller (option)

The media is detected by the ultrasonic sensor and rolled up automatically.

- Corresponding Models: FC9000-140/160

- Guaranteed accuracy length: 20m (Under 1.2m per job)

- Maximum diameter of winding roll: φ180mm

- Winding conditions:

– End face of roll media and end face of paper tube should be aligned.

– Width of roll media should be the same as width of paper tube at winding side. - It cannot be winded if media is folded or overlapped inside the basket.

Software

You can easily create and cut high quality designs with the standard included software.